limitless

variety

The polyurethane we use for our moulds is the result of a continuous development with a renowned German manufacturer. It guarantees the highest quality in the production of WetCast products.

highly extensible – extremely durable

- high dimensional stability – high dimensional accuracy

easy demoulding – smooth production process

- high abrasion resistance – long lifetime, low production cost

The right polyurethane for your product:

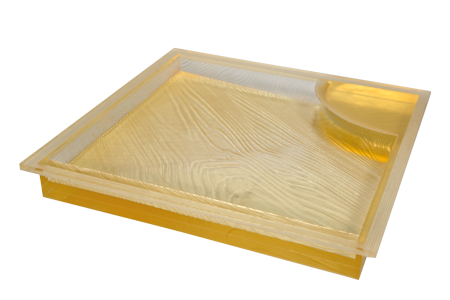

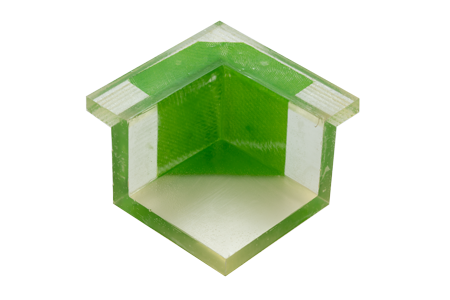

This high-performance polyurethane is particularly suitable for products with undercuts, for sophisticated side surface structures or for products with complex technical geometries. The polyurethane is characterized by high tear resistance and dimensional stability and is particularly suitable for manual production.

In cooperation with a renowned German manufacturer, we have continuously developed this polyurethane material. The result is a polyurethane for the highest quality standards with extreme durability, high dimensional stability and easy demoulding. These attributes are reflected in economy and profitability. This material can be used for both, small and large stone geometries and is particularly suitable for the machine production of WetCast products.

A proven and mature polyurethane, particularly suitable for large-volume products with simple side structures. This material is used in bus curbstones or block steps, for example.

Polyurethane moulds for high dimensional stability

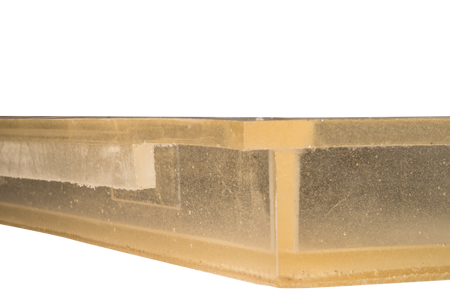

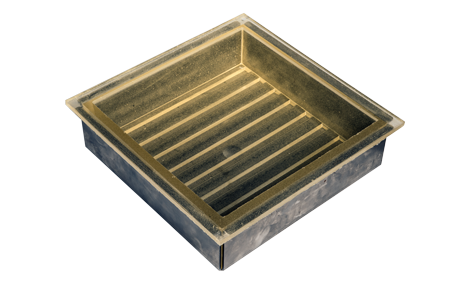

The skin around the mould is to prevent concrete residue from penetrating between the mould and the support frame, so that a dimensionally accurate product can be manufactured.

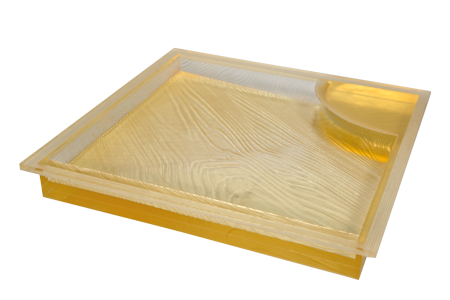

The overlip, the slip-on edge ensures that no concrete residue can penetrate between the mould and the support frame and, on the other hand, that the mould sits perfectly in the support frame. This version is particularly suitable for automatic demoulding.

A revolution in your manual production. Let us explain the advantages in a personal conversation!

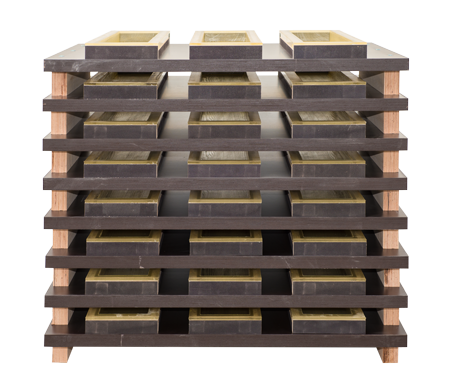

For perfect series production

wooden frames screwed on production boards